EDITED: 9/11/2013

The case study that I chose last week was the Living Machine installation at Port of Portland Headquarters in Oregon. The building uses both outdoor and indoor cells in the treatment process.

The building was designed by Zimmer Gunsul Frasca Architects (ZGF).

Information about this project can be found in the following links:

http://www.livingmachines.com/Portfolio/Municipal-Government/Port-of-Portland-Headquarters,-Portland,-OR.aspx

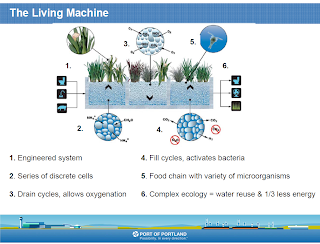

This link, provided by Living Machines, explains the type of living machine system used. A "Tidal Flow Wetland" Living Machine was used. It had 6 tidal flow cells that processed water before it was sent to "polishing." Polishing, as discussed in our last class, is the process of disinfecting the water with UV light. In this case, Chlorine was also used.

http://www.portofportland.com/prj_POP_HQP2_Home.aspx

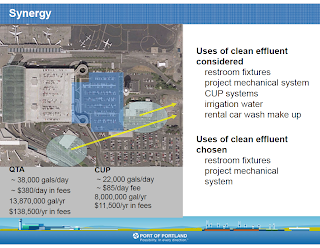

Many of these links share similar content however, this link shares that the project was awarded LEED platnum not LEED Gold. It also shares that the water was reused for toilets and the buildings cooling towers.

http://www.portofportland.com/Media_HQ_PressKit.aspx

The press kit for the Port of Portland building clarifies that this Tidal Flow system is MOSTLY indoors. The PDF below shows that there is one single outdoor cell.

http://www.greenbrokereducation.com/GBC%20Readings/portland_living_machine.pdf

This PDF explains/shows the components used in the building's Living Machine. This system actually differs from the system I initially researched for last week's class. The water flows from one cell into the next when it "floods." It also shows the outdoor polishing cell.

http://www.deq.state.or.us/nwr/permits/PortofPortlandWPCFEvaluation.pdf

This PDF is an evaluation of the Living Machine that was conducted by state inspectors. It is valuable because it actually shows the components of the system in use. It has actual site surveys and CD's for this system. Also included are specifications for each component.

http://sustainablewater.com/pdf/livingmachine/Portland.pdf

PDF is possibly the MOST useful of all of the PDF I was able to find. It has diagrams the entire process through the building. It is clear that the system doesn't require much vertical space to work. Gravity brings down the "black" water into the system for processing. The majority of the system, with the exception of the reuse and polishing tanks, are all in the lobby.

http://www.deq.idaho.gov/media/996940-gilkison_presentation_051613.pdf

This PDF was used in a presentation by Living Machine to discuss the effectiveness of this system. The thing to take from this PDF is the diagram that shows where the effluent tank was placed in relation to the rest of the system. Also important were the regulatory hurdles that weren't obvious in the previous links. For exmaple: how do users accept this system? And can this be adapted or added on to in the future?

— Josh

Josh,

ReplyDeleteInteresting project. Looks like a successful integration of the technology into the design.

Please provide a brief description of the project and annotations to the links (why someone should follow them) for the rest of the class. Please also give credit to the architect.

I couldn't follow all of the links - I'll try with another computer - but couldn't see that there was sufficient information to diagram the process through the building.

Hi William,

ReplyDeleteThank you very much for your feed back. I'm sorry you weren't able to access all of links. I have checked them all and they're functioning properly. I do hope you get a chance to see them. In case you can't, I've summarized the links. Making sure to note the "best" parts of the information I gathered. I'm taking screenshots of the best parts and posting them to my submission. Just in case.

If you think this is a poor case study, is there one you might recommend? I will diagram this one for class but am happy to change directions to better my understanding of this system.

I've added screenshots of the useful parts of the PDF in case people have issues opening the links.

ReplyDelete